We have two types of Cell Wall Cracking Machines in workshop to process our cell wall cracked pine pollen powder as:

Airflow Cell Wall Cracking Machine

Airflow cell wall cracking machine consists of air supply unit, feeding unit, grinding unit, powder grading unit and powder collecting unit. When the raw pine pollen is fed from the feeding mouth and mixed with the fresh compressed air from the air supply unit, the supersonic airflow generated by the ejector will makes the raw pine pollen granules/particles crash with each other and the cell wall will be damaged during this process. After the pine pollen granules/particles having reached the required fineness, they will be released by the grading unit on the top of the machine and are collected and packed by the powder collecting unit at the bottom of the machine.

Vibrating Cell Wall Cracking Machine

The raw pine pollen is fed into the crushing chamber through a hopper and crushed through crashing and grinding with grinding bar inside the chamber under the effect of vibration. And the machine is equipped with water cooling unit to control the temperature inside the crushing chamber. In addition, the machine is operated under full close conditions without dust flying and environmental pollution.

Comparison of Cell Cracked and Uncracked Pine Pollen

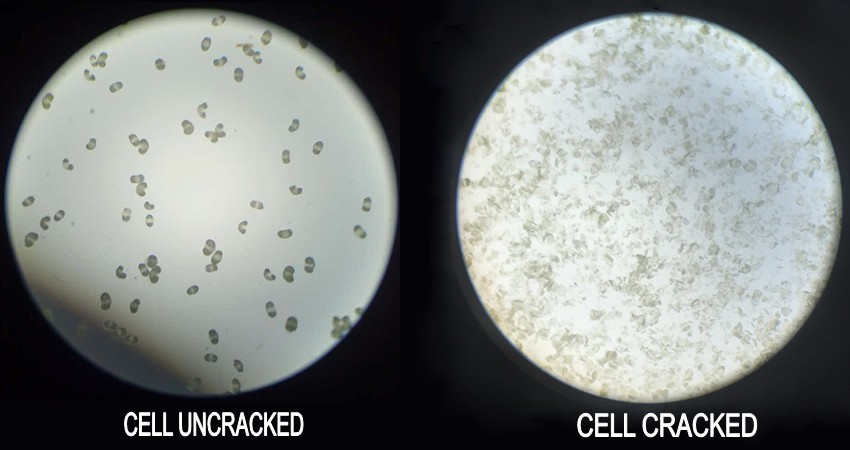

Uncracked pine pollen is much more golden yellow in color, entwisted with sense of lubrication, easy to lift up in the air. When uncracked pine pollen is shaken in a sealed transparent container, it could be found that it has a better flowability. In process of cell cracking, the appearance and some physical properties undergo changes. The color is changing to lighter yellow. Under the microscope, we could find airbag structures have been separated from pine pollen grain main structure and pine pollen grain is not complete like before. This will result in pine pollen looses its fluid/flowability characteristic, instead cell cracked pine pollen is with a strong adhesivity and is hard to lift up in the air.

Fig.1: Cell wall un-cracked pine pollen Fig. 2: Cell wall cracked pine pollen powder

Color: Golden yellow Color: Light yellow

Particle size: About 80 mesh Particle size: 300 mesh (cell cracked ratio>98%)

Character: Character:

1). Rough particle with obvious granular sensation; 1). Finer particle;

2). Easier to lift in the air with higher flowability; 2). Higher viscosity and lower flowability;

3). Weaker bitterness in taste; 3). Stronger bitterness in taste;

4). Most floating on the surface of water(Fig.3). 4). Most suspending or dissolving in water(Fig.3).

Nutrition Change after Breaking the Pine Pollen Cell Wall

With regard to whether pine pollen cell wall needs to be broken, some people believe the nutrition inside pine pollen cell wall could be released through germinal aperture. Before we make any judgement on this opinion, let’s focus on the structure of pine pollen first. It’s known that to preserve their own biological activities under different environments so as to reproduce when conditions are right; pine pollen are protected under a hard cell wall which is insensitive to many chemical reagents. This cell wall couldn’t be destroyed even when soaked and boiled in caustic soda, meanwhile it has been proven with strong radiation resistance. Japan is only nation that gone through nuclear strike in the world, which result in they pay special attention to radiation resistance researches. Japanese scholars once experimented on large dose of radiation and found the lethal dosage of radiation for human is only 1C(Coulomb)/KG while lethal dosage of pollen cell is 77.4-1291C(Coulomb)/KG. This experiment showed that cell wall of pollen is exceptionally hard and has strong radiation resistance.

The results of many past experiments showed that the precipitation rate of pine pollen nutrition is no more than 20% in neutral solution and pollen will produce a kind of protective response to stress so as to release much less nutrition through germinal aperture under the condition of acid and alkali. We also understand the acidity of gastric acid is so high that even bones or other hard stuff we eat could be completely digested; however gastric acid couldn’t dissolve the hard cell wall of pine pollen, pine pollen being excreted as how they be taken. Experiments so far show that digestive juice of human and monogastric animal can’t destroy cell wall of pollen. Therefore there are lots of domestic and overseas researches has be done on how to take pine pollen and to take most of nutrition contained in pine pollen.

Trace Element Research Lab of Clinical Medicine Research Institute of China PLA General Hospital has researched on the form and nutrition change of pine pollen before and after breaking the cell wall. They adopt High-speed Airflow Smashing technology at low temperature to break the pine pollen cell wall which could prevent exogenous pollution and guarantee nutrition won’t be damaged during cell wall breaking process. By observing the

pine pollen form under the microscope and comparing the nutrition change between raw pine pollen and cell wall cracked pine pollen, they researched the impact of cell wall breaking process on pine pollen structure and nutrition change.

Raw pine pollen is light yellow in color, entwisted with sense of lubrication, easy to lift up in the air with a light weight. When raw pollen is shaken in a sealed transparent container, we could find pine pollen has fluid characteristic. However the appearance and some physical properties changed after breaking the cell way by high-speed airflow smashing. Airbag structures have been smashed and separated from pine pollen grain main structure and main structure of pine pollen grain is relatively enriched. After breaking the cell wall, superficial area of pine pollen increased and lost its fluid characteristic, with a strong adhesivity which is hard to lift up instead.

During cell wall breaking process, pine pollen grain crash each other and then the airbag structures are separated from main structure under strong mechanical action. Due to unique physical structure, airbags are easily carried and damaged by high-speed airflow which result in pollen grain main structure are relatively enriched. It shows almost no difference in content of dry substance before and after breaking the pine pollen cell wall, 94.7% and 94.1% respectively, which could make a conclusion that moisture content change is small after breaking the cell wall. Other changes could be found in below chart as hemicellulose content decreasing dramatically from 12.8% to 1.5%, cellulose content from 14.4% to 9.9%, xylogen from 29.6% to 25.9%, coarse fiber from 35.6% to 27.3% and sugar from 12.3% to 18.7%. From above figures we could get the conclusion that pollen grain airbags are mainly composed by hemicellulose, cellulose, xylogen and so on.

| Item | Raw Pine Pollen | Cell Cracked Pine Pollen |

| dry substance | 94.70% | 94.10% |

| coarse protein | 12.70% | 13.10% |

| ether extract | 1.50% | 10.50% |

| total lipids | 7.30% | 10% |

| starch | 5.40% | 7% |

| Sugar | 12.30% | 10% |

| Soluble carbohydrate | 14.80% | 30.20% |

| hemicellulose | 12.80% | 1.50% |

| cellulose | 14.40% | 9.90% |

| xylogen | 29.60% | 25.90% |

| coarse fiber | 35.60% | 27.30% |

| Ash | 3.10% | 3.50% |

| total zinc content | 36.6μg/g | 37μg/g |

| soluble zinc content | 0.16μg/g | 0.26μg/g |

| total energy | 21KJ/g | 22.1KJ/g |

Soluble carbohydrate increasing from 14.8% to 30.2% after breaking the cell wall which double the content before; the content of ether extract going through a sharp jump from 1.5% to 10.5% which is 7 times higher than before, soluble zinc content also rising greatly from 0.16microgramme/gram to 0.26microgramme/g.

Below figures show the nutrition changes of pine pollen before and after breaking the cell wall, coarse protein content increasing from 12.7% to 13.1%, content of starch and total lipids increasing by around 30%, starch content from 5.4% to 7.0%, total lipids from 7.3% to 10.0%, total energy increasing by around 5%, ash increasing by 0.4%. These figures indicated that the main structures of pollen grain were relatively enriched.

| Type of amino acids | Raw pine pollen | Cell cracked pine pollen | ||

| Total amino acids(nmol/mg) | Free amino acids(nmol/mg) | Total amino acids(nmol/mg) | Free amino acids(nmol/mg) | |

| aspartic acid | 65.4 | 1.9 | 68.1 | 2.8 |

| threonine | 36.1 | 1.2 | 37.7 | 2.4 |

| serine | 43.5 | 2.4 | 46.8 | 4.2 |

| glutamic acid | 76.4 | 3.6 | 81 | 5.5 |

| proline | 35.5 | 28.8 | 39.4 | 29.5 |

| glycine | 67.5 | 2.5 | 68.8 | 2.2 |

| alanine | 64.9 | 8.7 | 67.3 | 9 |

| cystine | 5.4 | 0.2 | 5 | 0.2 |

| valine | 48.2 | 1.2 | 50 | 1.6 |

| methionine | 1 | 0.1 | 10.2 | / |

| isoleucine | 35.8 | 0.7 | 36.8 | 1 |

| leucine | 57.2 | 0.7 | 59.3 | 0.9 |

| tyrosine | 15.4 | 2.2 | 16.9 | 2.9 |

| phenylalanine | 27.1 | 1 | 27.8 | 1.3 |

| histidine | 16.9 | 12.9 | 19.6 | 13.7 |

| lysine | 50.4 | 0.6 | 53.3 | 1.5 |

| arginine | 36.7 | 9.3 | 35.9 | 11.8 |

Also we could see total amino acids content in cell wall cracked pine pollen are higher than raw pine pollen except cysteine, arginine and methionine, free amino acids content are also higher in cell cracked pine pollen except cysteine, glycine and methionine. Markedly increase of dissolving-out amount of water-soluble and liposoluble ingredients after breaking the cell wall is a powerful evidence to show the effectiveness of cell wall breaking process. All above figures could support the statement that cell wall breaking process could help the fully release of nutrition of raw pine pollen. Other technologies to break the pine pollen cell wall include Fermentation Wall-breaking, Colloid Grinding and so on. However High-speed Airflow Smashing could ensure cell wall breaking ratio above 99% which could greatly maximize the absorptivity of pine pollen nutrition for human.